PET FY1002

PET|聚对苯二甲酸乙二醇酯聚酯切片

规格级别:注塑

产品用途:主要用于油瓶矿泉水瓶油瓶酱油瓶宽口瓶

PET FY1002 瓶级聚酯切片是针对油瓶、酒瓶及PET片材的特有使用性能要求而开发生产的。

PET FY1002 产品具有色值好、乙醛含量低、粘度稳定的特点。

物性简介

PET(聚对苯二甲酸乙二醇酯/聚酯)/FY1002

用途:水瓶级

特性备注:色值好,乙醛含量低,粘度稳定,优良的加工性能,加工温度较低,加工范围宽,制品透明性好,成品率高。

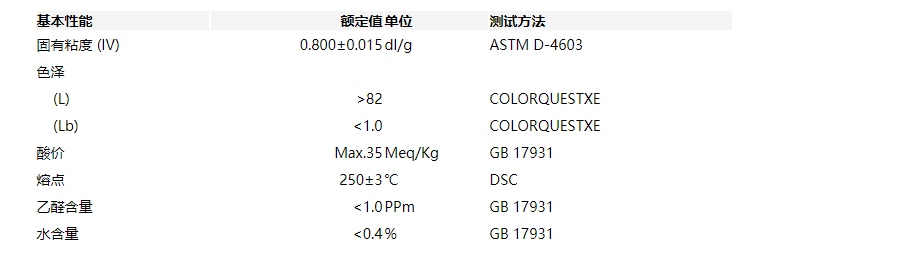

重要参数:

生产厂商: 尼沃广州

PET FY1002 注塑工艺特性与工艺

PET FY1002 PET polyethylene terephthalate polyester slice Specification level: Injection molding product Purpose: Mainly used for oil bottles, mineral water bottles, oil bottles, soy sauce bottles, wide mouth bottles, PET FY1002 bottle grade polyester slice is developed and produced for the specific performance requirements of oil bottles, wine bottles and PET sheets. PET FY1002 has the characteristics of good color value, low acetaldehyde content and stable viscosity.

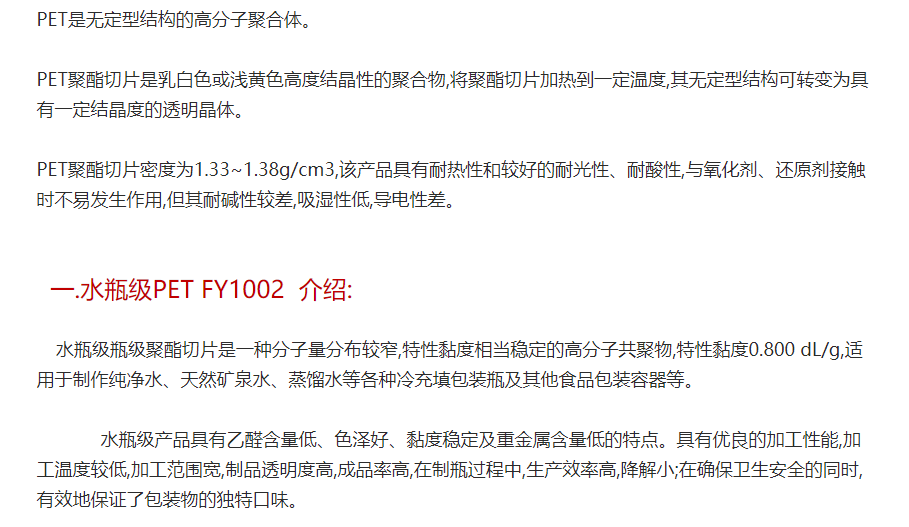

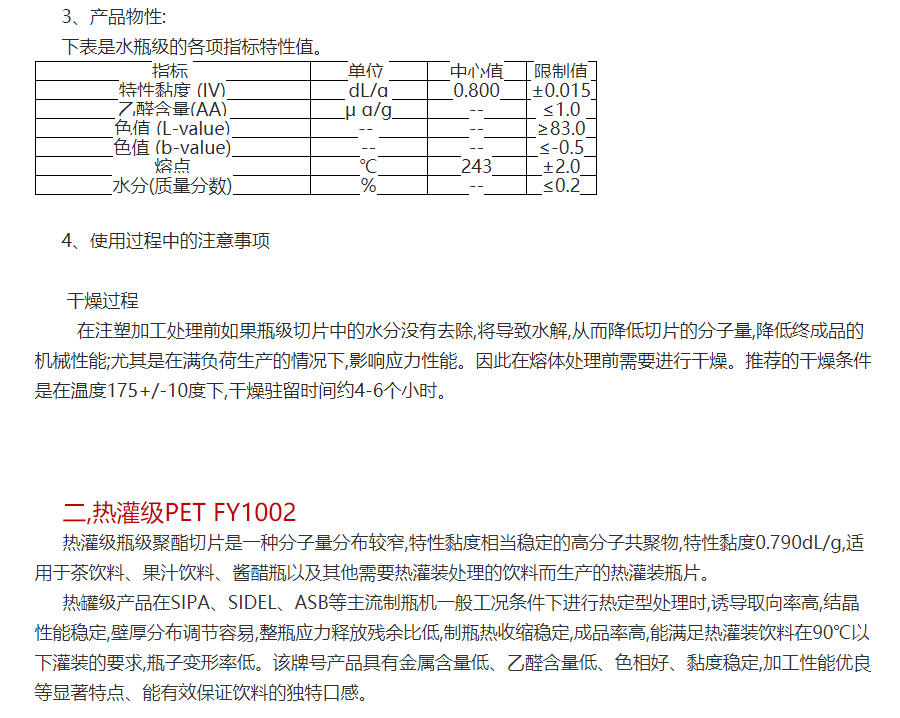

PET is an amorphous polymer. PET PET chips are milky white or light yellow highly crystalline polymers. When heated to a certain temperature, the amorphous structure of PET chips can be transformed into transparent crystals with a certain degree of crystallinity. PET polyester slice density is 1.33~1.38g/cm3, the product has heat resistance and good light resistance, acid resistance, and is not easy to act when in contact with oxidants and reducing agents, but its alkaline resistance is poor, low moisture absorption, poor electrical conductivity. Water bottle grade PET FY1002 Introduction: water bottle grade polyester slice is a kind of molecular weight distribution is narrow, the characteristic viscosity is quite stable polymer copolymer, the characteristic viscosity of 0.800dL /g, suitable for the production of pure water, natural mineral water, steam retention water and other cold filling packaging bottles and other food packaging containers. Water bottle products have the characteristics of low acetaldehyde content, good color, stable viscosity and low heavy metal content. It has excellent processing performance, low processing temperature, wide processing range, high product transparency, high yield, in the process of bottle making, high production efficiency, small degradation; In order to ensure the health and safety at the same time, effectively ensure the unique taste of the packaging.

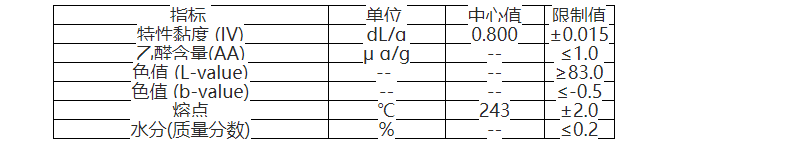

3, product physical properties: the following table is the water bottle level of each indicator characteristic value.

4. Precautions in the process of use if the moisture in the bottle section is not removed during the drying process before injection processing, it will lead to hydrolysis, thereby reducing the amount of section and reducing the mechanical properties of the final product; Especially in the case of full load production, the stress performance is affected. Therefore, it is necessary to dry the melt before treatment. The recommended drying conditions are 175+/-10 degrees with a drying dwell time of about 4-6 hours. Second, hot irrigation grade PET FY1002 hot irrigation grade bottle grade polyester slice is a kind of high grade copolymer with narrow distribution and fairly stable characteristic viscosity. The characteristic viscosity is 0.790dL/g. It is suitable for hot filling bottle slice produced by tea drinks, fruit juice drinks, vinegar bottles and other beverages that need hot filling treatment. Hot pot level product in mainstream SIPA, SIDEL, ASB our bottle blowing machine heat styling treatment under general conditions, the high rate of induced orientation, crystallization performance is stable, wall thickness distribution adjustment easy, stress release residual ratio is low, the bottle bottle manufacturing heat shrinkable stability, high yield, can satisfy the hot filling beverage filling under 90 ℃, the bottle deformation rate is low. The product has the characteristics of low metal content, low acetaldehyde content, good color, stable viscosity, excellent processing performance and so on, which can effectively ensure the unique taste of the drink.

PET(polyethylene terephthalate/polyester)/FY1002

Application: Water bottle grade

Good color value, low acetaldehyde content, stable viscosity, excellent processing performance, low processing temperature, wide processing range, good product transparency, high yield.

Important Parameters:

Manufacturer: Nevo Guangzhou

PET FY1002 injection molding process characteristics and technology.

The drying temperature 80°C

The drying time 3-4 hours

The water content 0.02%

Melt temperature 245-260 ° C

Nozzle temperature 240-255 ° C

Before the zone temperature 245-260 ° C

In the middle 240-255 ° C

The back of the 230-250 ° C

Mold temperature 50-75 ° C

Back pressure 0.3-0.7 MPa